PVC embraces sustainable building with its sustainability, recyclability and energy conservation, which allow lighter, longer lasting buildings which reduce emission and wastage in green building. It is environmentally friendly with such certifications as LEED since it uses less resources and less lifecycle than wood, steel, or concrete. This flexibility leads to green designs without compromising performance.

Durability and Longevity

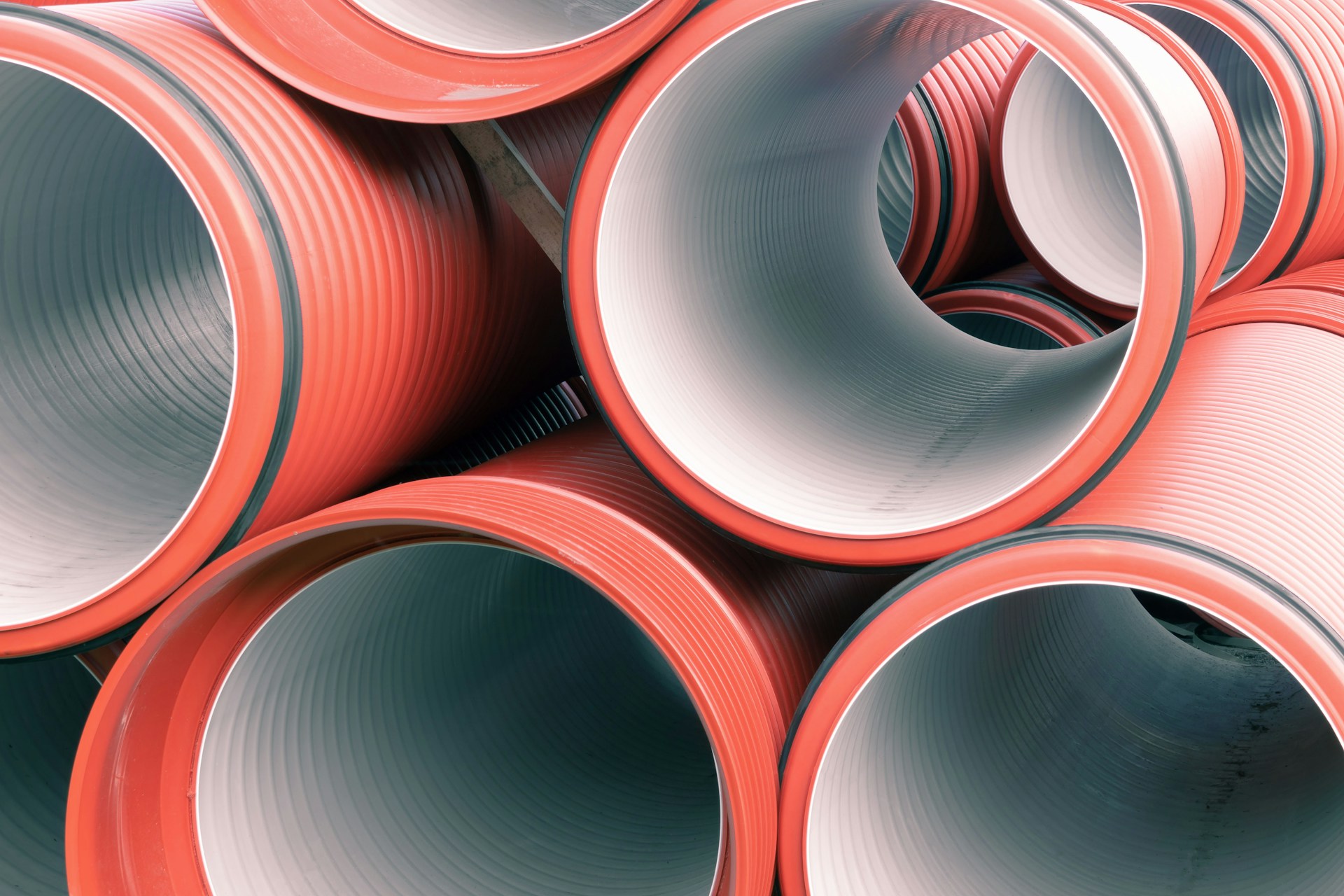

PVC products have a life span of more than 50-100 years, which is resistant to corrosion, chemicals, and weather hence reducing replacement and wastage. Pipes do not have jagged interiors and reduce pumping energy by half, as well as water loss, which is crucial to efficient plumbing in green buildings. In comparison to wood which decays or metals which rust, PVC provides structural integrity, which supports net-zero objectives by maintaining a long service life.

PVC products have a life span of more than 50-100 years, which is resistant to corrosion, chemicals, and weather hence reducing replacement and wastage. Pipes do not have jagged interiors and reduce pumping energy by half, as well as water loss, which is crucial to efficient plumbing in green buildings. In comparison to wood which decays or metals which rust, PVC provides structural integrity, which supports net-zero objectives by maintaining a long service life.

Energy Efficiency Gains

Light PVC reduces the emissions in the air and makes the installation process easier, whereas the high-quality insulation in the windows and panels reduces the heating requirements by three times compared to aluminum. It consumes less energy than steel or copper, and integration of recyclates will save 45-90% more, increasing high-rise or retrofits savings. The characteristics increase building energy performance ratings, which are important to green standards.

Light PVC reduces the emissions in the air and makes the installation process easier, whereas the high-quality insulation in the windows and panels reduces the heating requirements by three times compared to aluminum. It consumes less energy than steel or copper, and integration of recyclates will save 45-90% more, increasing high-rise or retrofits savings. The characteristics increase building energy performance ratings, which are important to green standards.

Recyclability and Waste Reduction

Thermoplastic PVC is recycled, and templates can be used more than 20 times, which means that garbage will not go to the landfill and the forests will be saved- 1 ton will save 1 cubic meter of wood and 1.82 tons of CO2. CLS Recycled pipes are used to create profiles and stimulates the construction site in the circular economy. This will cut down on virgin material requirements, which is in line with the sustainable sourcing requirements.

Resource Conservation

PVC is made out of salt and oil, which require less non-renewables than the metals, which require mining, and the WPC blends include recycled plastics and agricultural wastes. Minimal maintenance also reduces maintenance costs and corrosion resistance also removes chemical treatments applied on substitutes. Each ton deployed saves oil, coal and land, promoting four saves policies.

PVC is made out of salt and oil, which require less non-renewables than the metals, which require mining, and the WPC blends include recycled plastics and agricultural wastes. Minimal maintenance also reduces maintenance costs and corrosion resistance also removes chemical treatments applied on substitutes. Each ton deployed saves oil, coal and land, promoting four saves policies.

Certifications and Real-World Impact

PVC can be credited in LEED, low carbon and recyclability in BREEAM, and is used in powering projects such as energy-efficient housing and infrastructure. There are innovations such as PVC-O pipes, which are stronger using less material, and panels which can be assembled in large-scale construction in a short amount of time with a minimal amount of waste. Millions of cubic meters of timber is saved each year by adoption globally and this is evidence of the role of PVC in resilient and green urban development.